27.04.2021

Initial release of hydrogen from liquid organic carrier medium (LOHC) for gas analysis at research partner VTT in Espoo. Whole logistical chain including hydrogen storage in Kokkola, transportation in LOHC and release in Espoo will be demonstrated by Woikoski and VTT as well as supported by Hydrogenious LOHC with O&M services

Kokkola & Espoo/Finland, Erlangen/Germany, 27 April, 2021.

Despite the restrictions imposed by the Covid-19 pandemic, the HySTOC EU project initiated in January 2018 and located in Finland has reached important milestones in successful cooperation between its Finnish, Dutch and German partners: The Liquid Organic Hydrogen Carrier plant system from the German market leader Hydrogenious LOHC Technologies for the storage and release of hydrogen from the liquid carrier medium has started operation without any problems at local double-digit sub-zero temperatures. Now, the participating Finnish research institute VTT in Espoo is operating the hydrogen release plant and testing the quality of the re-released hydrogen over a minimum period of six months. The released hydrogen is planned to fulfil very strict purity demands in order to be applicable with fuel cell vehicles. Afterwards, there is nothing technically standing in the way of installing the so-called release box at its final destination, a public hydrogen filling station.

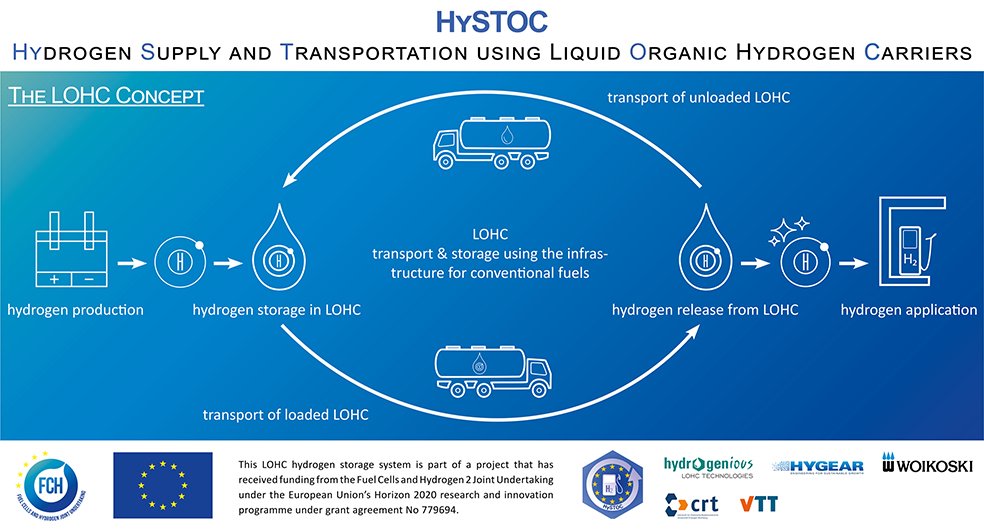

The EU project HySTOC stands for "Hydrogen Supply and Transportation using liquid Organic Hydrogen Carriers". The aim of the project is to establish and test an efficient hydrogen value chain in Finland, from production (Kokkola site, partner company Oy Woikoski AB) to use in the mobility sector via a hydrogen filling station, in order to facilitate international learning. The proprietary LOHC technology of the German Hydrogenious LOHC Technologies GmbH and its plant systems based on it are the linking component. By connecting the hydrogen to the Erlangen-based company's liquid carrier material, it can be easily and safely transported to any customer using conventional logistics for liquid fuels at ambient conditions and released from the carrier there. With the so-called Pressure Swing Adsorption (PSA) of the project partner HyGear, the hydrogen released from the LOHC is purified to hydrogen fuel standards, for refuelling cars or trucks with fuel cell engines. The VTT Technical Research Centre of Finland and the German Friedrich-Alexander University Erlangen-Nuremberg (Chair of Chemical Reactor Technology) are the scientific research partners in HySTOC.

Hydrogenious LOHC Technologies' StorageBox, shipped in March 2020, has now been successfully commissioned at the Woikoski’s hydrogen production site in Kokkola – despite the local -23 degrees Celsius. The StorageBox in the project can store around 22 kilograms of hydrogen per day, bound to approximately 480 litres of the carrier medium. The ReleaseBox corresponding to the volume, which was delivered in November 2020 to VTT’s Bioruukki test facilities in Espoo, also went into operation. Hence, a central phase in the project has now started: The ReleaseBox will be operated in Espoo over 2,000 hours and the quality of the released hydrogen will be scientifically tested. This is because the purity of the hydrogen according to ISO 14687:2-2019 must be ensured for use in fuel cells. Additionally, VTT will study the effect of certain selected impurities in a 1 kW PEM FC system (Proton-Exchange Membrane fuel cell) at representative automotive conditions at steady state and cyclic operation.

“VTT has a long history in gas analysis and PEMFC research, this knowhow will be utilized in HySTOC project in order to understand the full potential of this LOHC-based technology for automotive applications,” comments Dr. Saara Viik the project manager at VTT. VTT’s experts finalized a full life cycle and techno-economic assessment of this technology last year and found out that this can be both environmentally and economically sustainable compared to pressurized or liquid hydrogen. If everything goes as planned, within six months, Woikoski’s PEMFC vehicle will be fuelled with the hydrogen from the ReleaseBox.

Operations in Woikoski has started softly. The company’s role started in implementation. It established the test facilities and assembled the StorageBox/ReleaseBox and assisting operational systems (electricity, automation and pumping systems) required to both Kokkola Hydrogen Production Site and in Espoo VTT, in co-operation with the organization. It went smoothly despite the corona pandemic, and the typical Finnish winter season with its’ freezing periods time to time. Woikoski is also producing the hydrogen for the test in the Kokkola Hydrogen plant, then binding the hydrogen to the liquid organic carrier material, with the assembled technology. Furthermore, Woikoski is responsible for transporting the LOHC to Espoo and release the hydrogen from the LOHC in the ReleaseBox, to be scientificallyt tested by VTT.

“The knowledge gained in the HySTOC project is significantly contributing to the further standardisation and scaling of our LOHC technology”, explains Dr. Marcus Guzmann, Chief Commercial Officer of Hydrogenious LOHC. “At the same time, the HySTOC project in Finland is now kind of competing with another LOHC project of ours, supplying a hydrogen refuelling station in Erlangen/Germany (partner H2 Mobility). It gets exciting to see where the first practical start will take place and where the logistical chain of LOHC-based technology is demonstrated from electrolysis to wheels for the first time.”

Back to listing